Hi there! Nice to meet you!

My name is Irving Zhang, a mechanical engineer and an artist.

To describle me in three words:

Self-Motivated | Curious | Collaborative

I work at the intersection of engineering rigor and hands-on making, with experience in mechanical design, CAD modeling, and prototyping. I enjoy turning ideas into physical systems through fabrication, testing, and iteration.

I value engineering that is practical, human-centered, and buildable, and I’m seeking opportunities to contribute to real-world solutions while continuing to grow as a designer and engineer.

-

I enjoy solving real-world problems through precision, structure, and iteration. From CAD modeling to system integration and prototyping, engineering challenges push me to think critically and build with intent.

→ Explore related work in the PROJECTS section. -

Design is how I organize and communicate ideas visually. I focus on clean, purposeful layouts that balance function and clarity, whether in technical diagrams or editorial-style compositions.

-

Art fuels my creativity and sharpens my attention to detail. Through sketching and digital illustration, I explore form, texture, and expression, complementing my technical work with visual intuition.

experience

-

Acquired and reconstructed cross-sectional geometry of biological tissue samples using robotic-arm laser scanning and Geomagic, supporting strain analysis in mechanical testing, improving dimensional accuracy by 15% and enabling repeatable prototype analysis.

Performed multi-angle strain analysis using extensometers and digital image correlation (DIC) via VIC-2D, improving data precision by ±5% compared to previous protocols, translating sensor data into material curves for FEA input.

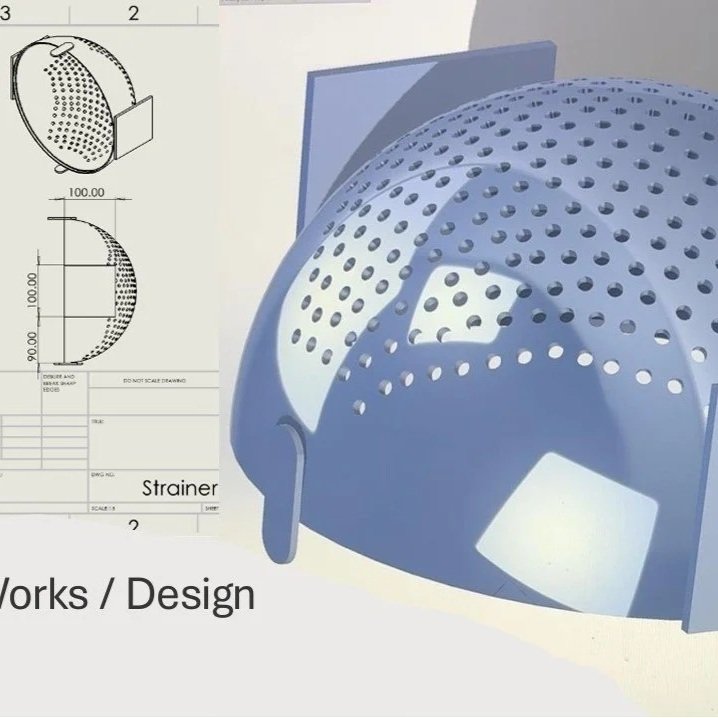

Designed custom fixtures in SolidWorks, collaborating with machinists to validate toolpaths and streamline prototype assembly for mechanical testing.

May – Aug 2025, Orthopaedic Engineering Lab, University of Pittsburgh

Applied Engineering research

Test & Validation

Cross-Functional Collaboration

-

Managed chemical inventory and maintained lab instruments to ensure uninterrupted testing operations and compliance with safety standards.

Ensured compliance with safety protocols for chemical handling and storage.

Provided customer-facing support for 30+ students per week, resolving equipment-related questions and maintaining a professional lab environment under high-pressure conditions.

Nov 2024 – Now University of Pittsburgh

Laboratory Operations

Safety & Compliance

Customer Support

-

Operated and maintained SLA/FDM 3D printers, CNC equipment, and machining tools, supporting safe and reliable prototype fabrication in a shared manufacturing environment.

Assisted in identifying fixture and setup constraints in CNC workflows and supported process adjustments and fixture/tooling development that helped improve average customer setup time and experience.

Supported robotic prototype builds by assisting with technical validation & advice, component sourcing, and basic documentation for startup engineering teams.

Nov 2025 – Now, Robotics Factory

Innovation Works, Pittsburgh, PA

Prototyping & Fabrication Support

Manufacturing Operations

Startup Engineering Assistance

Featured ProJects

paper roll convey machine design

Mechanical System Integration

Product Coordination

Cost Optimization

Strainer redesign

Human Factors Engineering

Ergonomic Product Design

User Safety & Usability

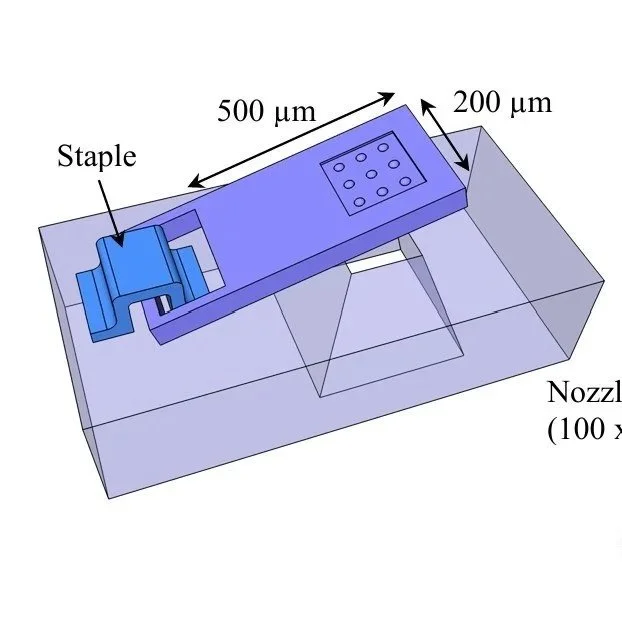

MEMS Check Valve Process Design

MEMS Microfabrication

Process Flow Design

Manufacturing Feasibility