MEMS Check Valve Process Design

📍 Duration / Institution

Dec 2025, University of Pittsburgh

⭐Tags

MEMS Microfabrication

Process Flow Design

Manufacturing Feasibility

⭐ Situation + Task

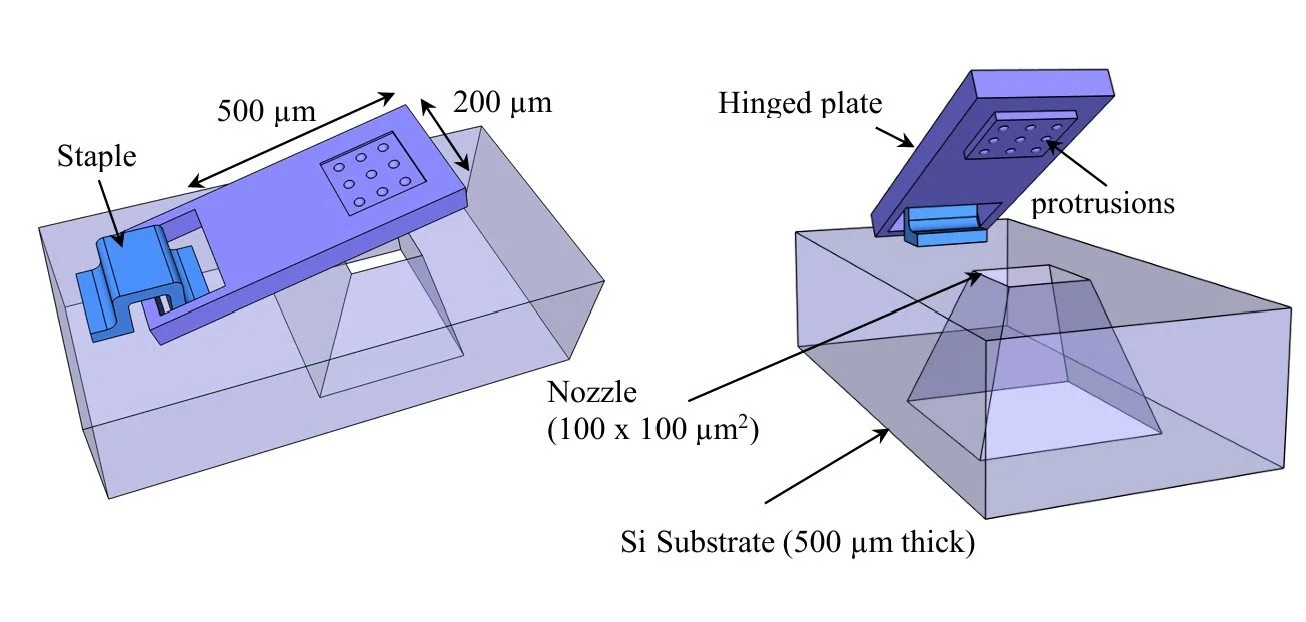

This project focused on designing a manufacturable MEMS process flow for a micro-scale check valve. The goal was not to redesign the valve structure itself, but to develop a clear, feasible fabrication sequence that enables reliable release and function while minimizing process complexity, cost, and failure risks.

⚙️ Action

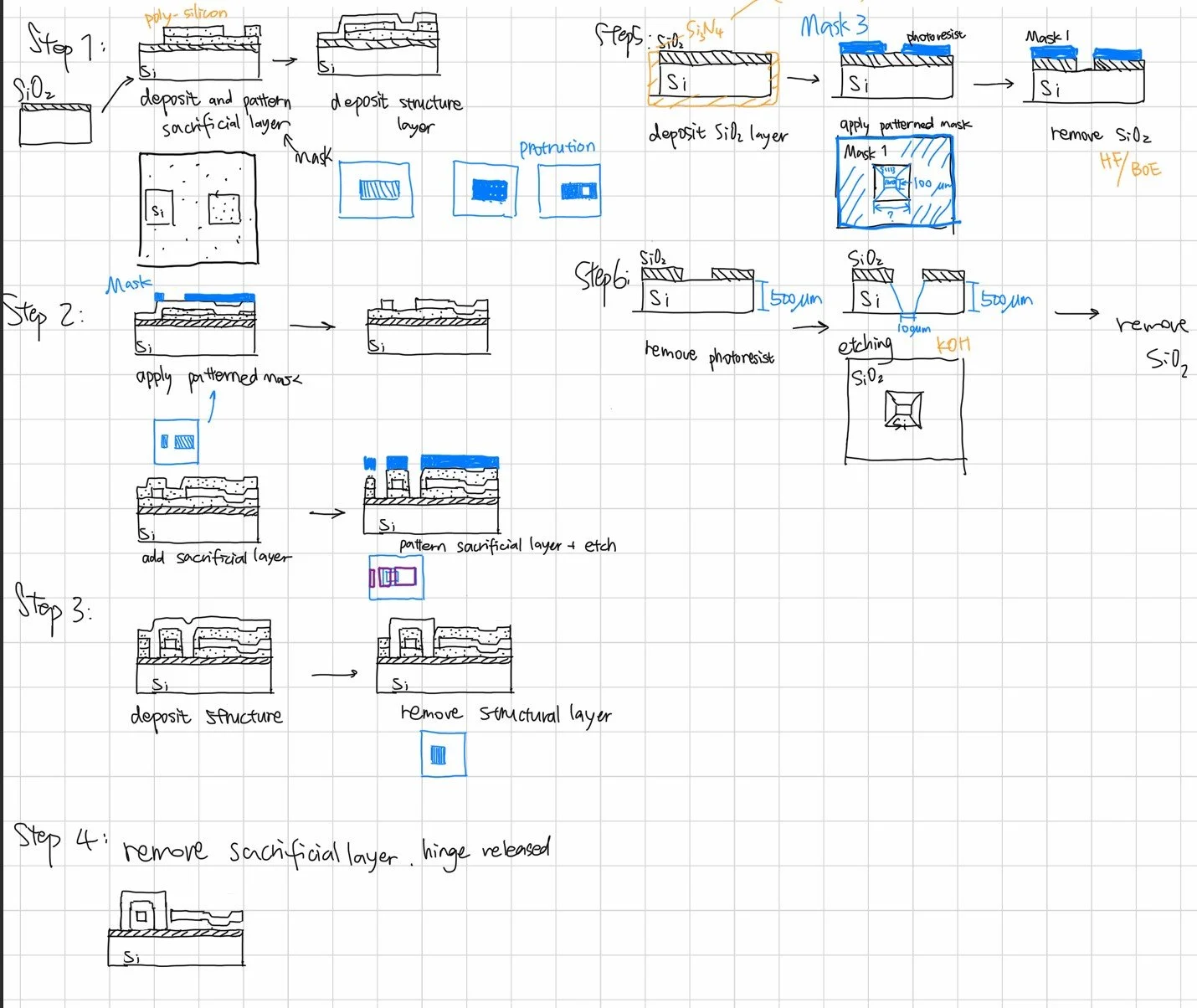

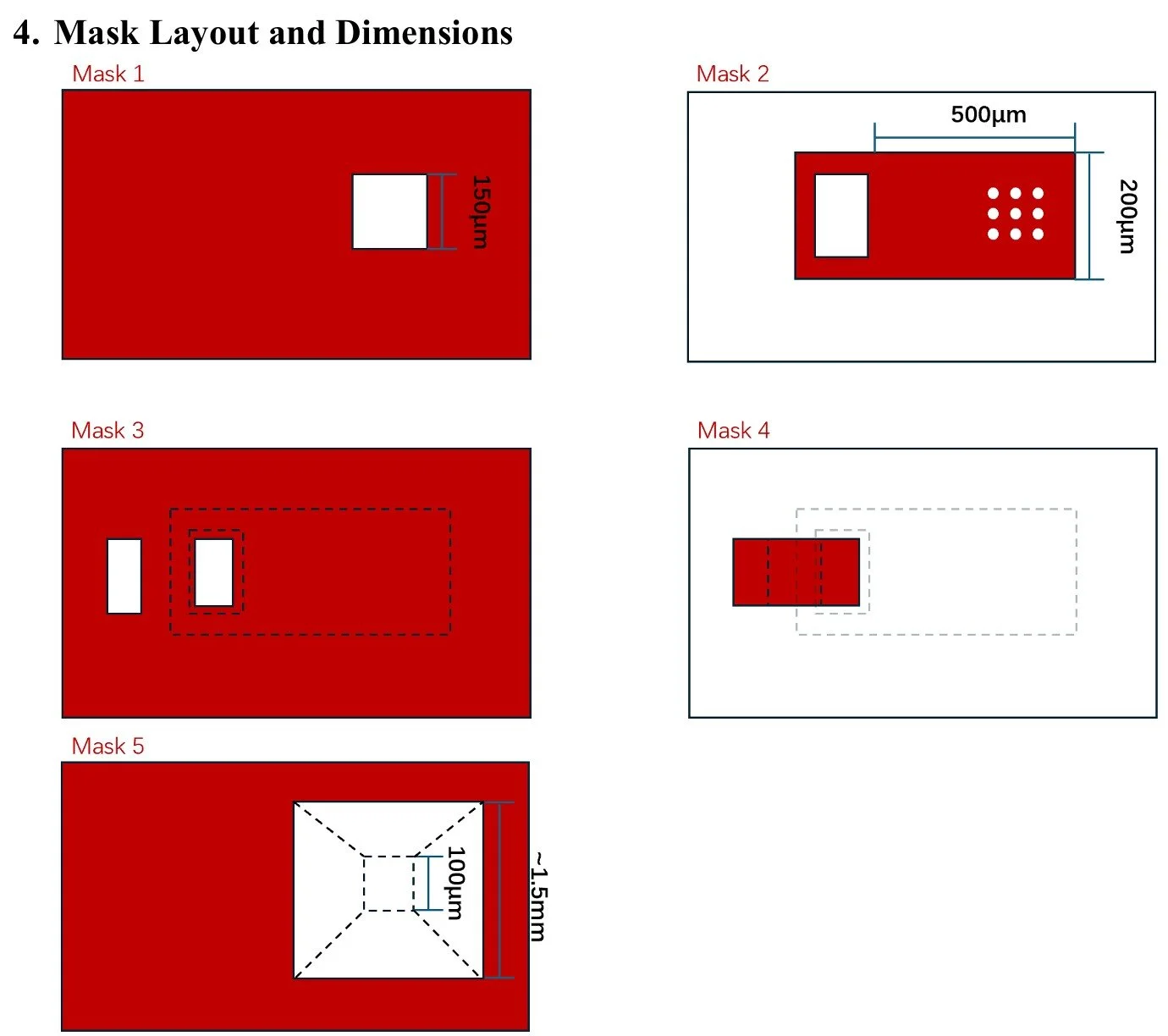

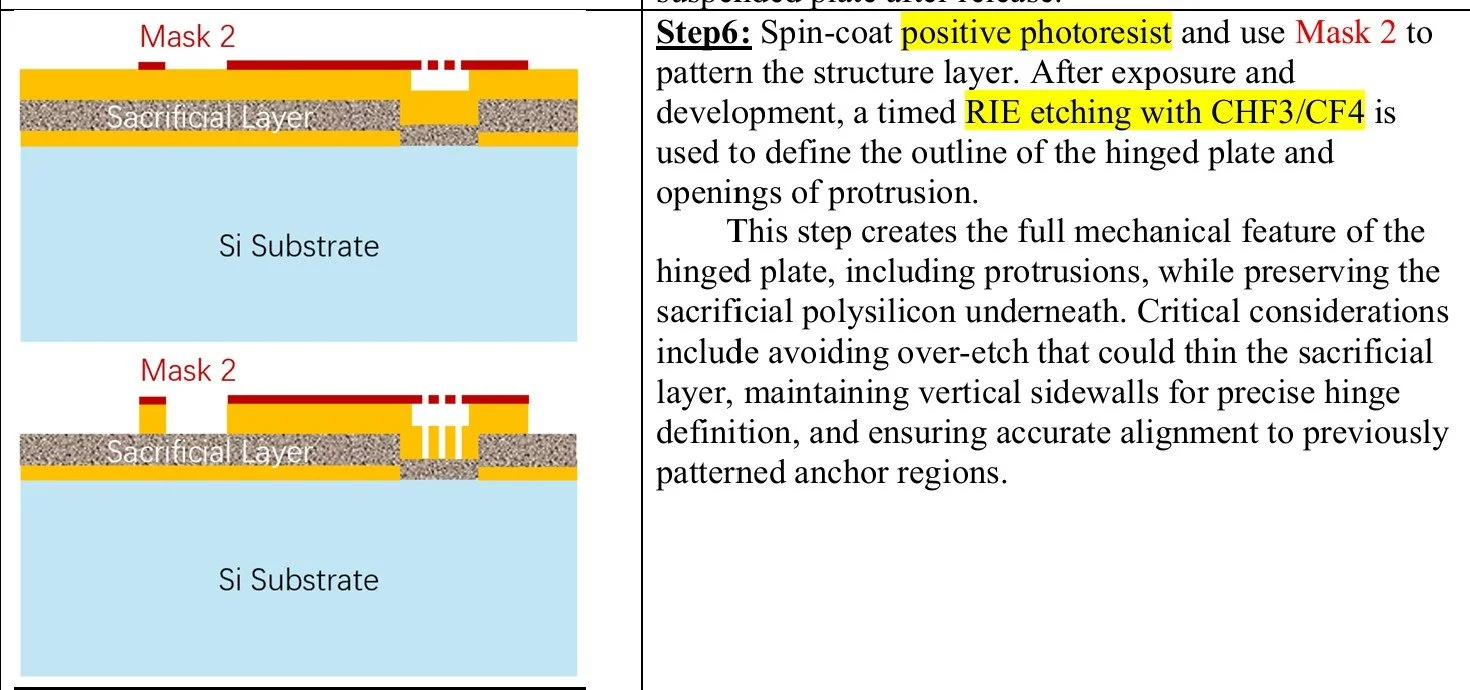

Designed a complete MEMS process flow, defining mask order and step-by-step sequences for deposition, lithography, etching, and sacrificial release.

Selected materials and fabrication methods (Si substrate, SiO₂ structural layers, sacrificial layers) based on etch selectivity, thermal compatibility, and process robustness.

Evaluated key manufacturing risks such as stiction, undercutting, and over-etching, and incorporated process-level mitigations to improve yield and reliability.

Optimized the process for manufacturability and scalability, reducing the total number of fabrication steps and mask usage while maintaining functional feasibility.

📈 Result

Delivered a manufacturable MEMS process design demonstrating a clear understanding of microfabrication constraints, tradeoffs, and yield considerations.

The final process flow shows how careful sequencing and material selection enable reliable MEMS device fabrication without unnecessary complexity.